AWS for Industries

Simplifying Industrial Equipment Monitoring with native anomaly detection in AWS IoT SiteWise

Manufacturing companies face significant challenges with unplanned equipment downtime, which leads to lost revenue and production delays. Maintenance teams often struggle to detect early warning signs of equipment failure due to resource constraints and a lack of advanced analytics expertise. To address these challenges, we are excited to announce the general availability of native anomaly detection in AWS IoT SiteWise. This new feature enables easy implementation of predictive maintenance strategies without requiring machine learning (ML) expertise.

In this blog post, we will explain how native anomaly detection in AWS IoT SiteWise helps organizations shift from reactive to proactive maintenance. This approach prevents costly downtime while maximizing equipment availability.

Unlock your IoT data with AWS

AWS offers a range of specialized IoT services that drive innovation in manufacturing, consumer products, automotive, and healthcare industries. These services help you accelerate innovation, secure your IoT applications from cloud to edge, and integrate AI and ML easily and at scale.

AWS IoT SiteWise is a purpose-built, managed IoT service that makes it easy to collect, store, organize, and monitor data from industrial equipment at scale to help you make better, data-driven decisions. It empowers companies to efficiently gather data from a wide array of industrial equipment and processes, create digital models of assets and facilities, process and analyze information in near real-time, and seamlessly integrate with other AWS services for advanced analytics, visualization, and ML applications. The built-in anomaly detection feature allows industrial companies to detect equipment anomalies across their fleet without writing code or managing complex ML systems.

Key benefits of native anomaly detection

Simplified configuration

Maintenance teams face significant challenges when implementing traditional anomaly detection systems. Typical solutions require complex integrations across multiple services such as Amazon S3, Amazon SageMaker, AWS Lambda, and Amazon Kinesis. Each service handles different aspects of data collection, storage, and processing. This process demands custom development for ML model training and deployment, specialized expertise in both ML and cloud architecture, and significant time and resources for implementation and management. Industrial IoT (IIoT) adoption faces major barriers due to workforce skill shortages and integration complexity. Implementation typically takes weeks or months and requires significant IT resources. Also, the ongoing maintenance of these multi-service integrations further adds to the complexity and resource demand.

Native anomaly detection in AWS IoT SiteWise addresses two key challenges in implementing ML-powered predictive maintenance in industrial environments:

- Removes the need for specialized machine learning expertise, making advanced analytics accessible to maintenance teams.

- Allows organizations to adjust monitoring frequencies to optimize cost.

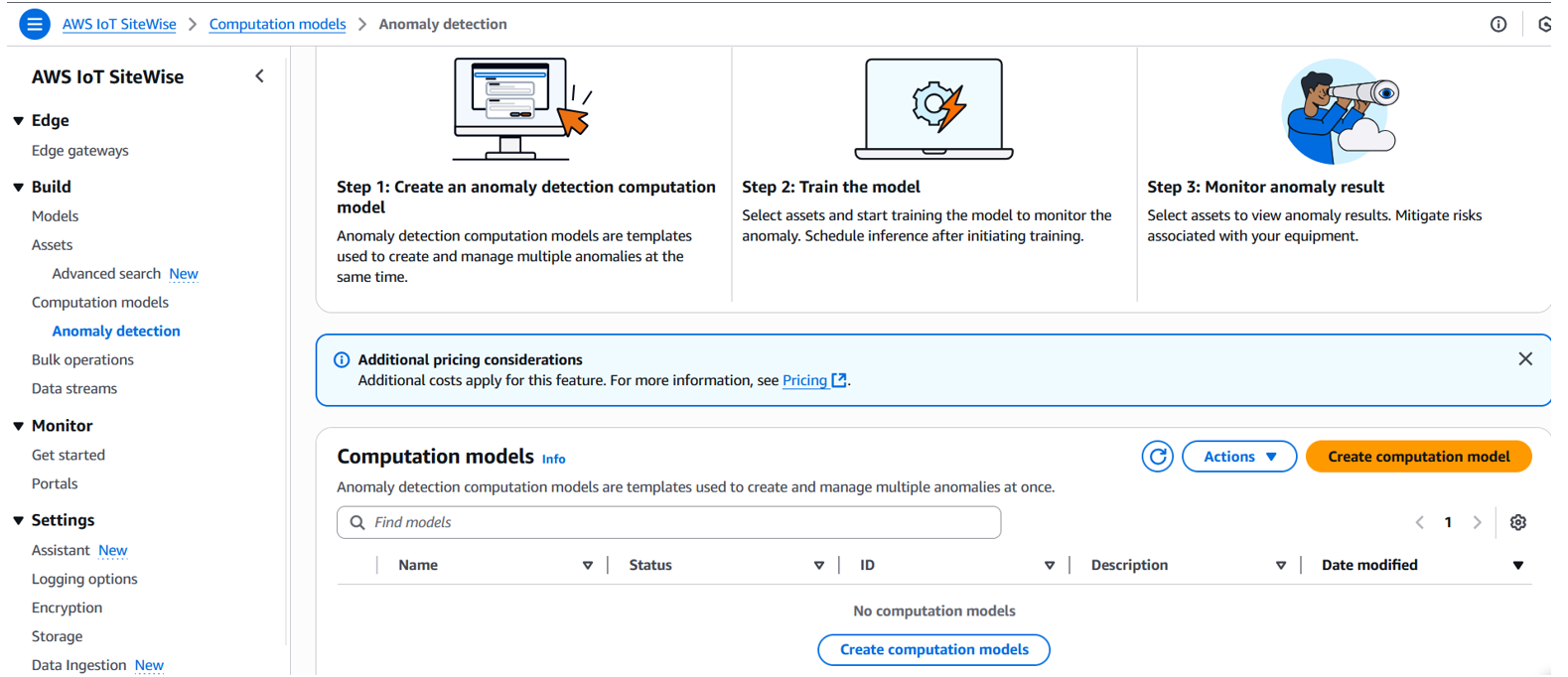

AWS IoT SiteWise’s native anomaly detection enables engineering teams to detect upset conditions on industrial assets in minutes through a simple, no-code configuration workflow. The setup process involves:

- Selecting relevant properties from existing asset models or assets in AWS IoT SiteWise.

- Training anomaly models with as little as 14 days of historical data.

- Optionally include labeled data to improve model accuracy.

- Setting preferred monitoring frequency for anomaly detection.

AWS IoT SiteWise automatically manages all aspects including data preparation, model training, deployment, and inferencing. Users can visualize inference results using the AWS IoT SiteWise plugin in AWS Managed Service for Grafana or by connecting to your existing maintenance dashboards using APIs.

AWS IoT SiteWise allows you to configure anomaly detection models on assets and asset models in minutes. This feature removes complex integrations and ML expertise requirements, allowing maintenance teams to focus on maintaining equipment reliability. Organizations of all sizes can now implement advanced preventive maintenance to reduce unplanned downtime and improve operational efficiency.

Figure 1: View of the anomaly detection feature in the AWS IoT SiteWise

Flexible monitoring options

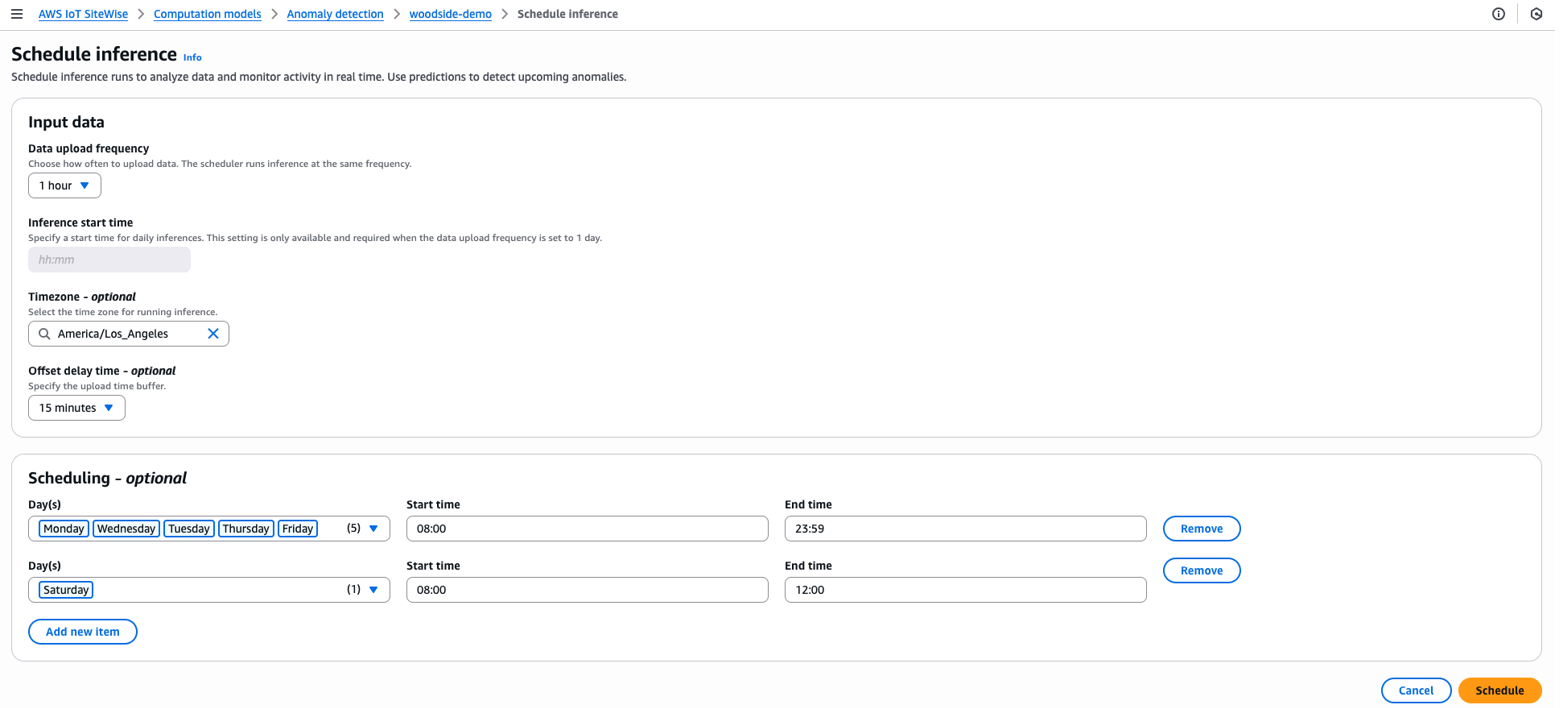

In industrial environments, the diverse array of equipment and assets demands a flexible approach to anomaly detection. Native anomaly detection in AWS IoT SiteWise addresses this need by offering flexible monitoring options that cater to varying asset types and monitoring requirements. You can schedule asset inference monitoring at intervals ranging from five minutes to once per day, including accommodation for planned downtime. This flexibility allows you to tailor anomaly detection strategies to each asset’s specific requirements and your operational needs. This range enables organizations to precisely match their anomaly detection strategy to the specific needs of each asset. For example, for assets like turbines, compressors, or production machinery where rapid detection of anomalies is critical to detect unexpected outages or deviations, inferencing would be set to occur every 5 minutes. Less critical assets, like auxiliary pumps, HVAC systems, or non-critical conveyor belts, can be monitored less frequently and still maintain operational integrity. These assets typically range from hourly to daily intervals, striking a balance between timely anomaly detection and resource utilization.

This flexible approach empowers organizations to optimize the cost of their anomaly detection to their specific operational requirements. By matching monitoring frequency to asset criticality, maintenance teams can optimize their maintenance efforts, focusing resources on delivering the most impact, while managing costs effectively. Furthermore, this flexibility allows for easy adjustments as operational priorities evolve, ensuring that your anomaly detection strategy remains aligned with your changing business needs.

Figure 2: AWS IoT SiteWise inference scheduling interface

Automated intelligence

Native anomaly detection is powered by a fully automated backend that abstracts away the complexities of machine learning and data science. This intelligent system works behind the scenes, enabling maintenance teams to harness the power of advanced analytics without the need for specialized expertise.

The automated workflow consists of several key steps:

- Data preparation: AWS IoT SiteWise preprocesses the industrial data, handling normalization, missing value imputation, and feature engineering. This ensures optimal data format for anomaly detection, regardless of the original source.

- Model selection and training: AWS IoT SiteWise selects and trains the most appropriate machine learning model based on specific asset and data characteristics. This process, typically requiring significant data science expertise, is fully automated.

- Continuous evaluation: The system continuously assesses model performance to adapt to changing operational patterns or newly labelled anomalies.

- Deployment: AWS IoT SiteWise deploys trained models into your environment for real-time inferencing on incoming data streams. This runtime environment is fully managed, ensuring high availability and scalability without any operational overhead.

- Results integration: Anomaly detection results are integrated back into AWS IoT SiteWise and existing data structures, enabling immediate visibility of potential issues and seamless incorporation into operational workflows and visualization tools.

By automating these complex technical processes, AWS IoT SiteWise allows maintenance teams to focus on interpreting results, making informed decisions, and maintaining equipment reliability. The service manages the intricacies of machine learning and data processing, while teams apply their domain expertise to drive tangible operational improvements.

Seamless integration and accessibility

In industrial operations, one size rarely fits all. AWS IoT SiteWise native anomaly detection is designed to adapt to your operation’s needs. Whether you’re a maintenance team looking for faster insights or a developer building a custom solution, the integration framework offers flexible paths to adoption:

AWS IoT SiteWise Console – No-code Configuration

The AWS IoT SiteWise console provides an intuitive interface for maintenance teams to configure and manage anomaly detection without writing code. Through the console’s guided workflow, you can select assets and map properties with a few clicks. The interface enables rapid deployment of monitoring across your entire fleet of assets, whether you’re tracking a single machine or hundreds of distributed equipment. Centralized configuration management gives you complete visibility and control over your monitoring setup.

APIs for Custom Integration

For organizations that need programmatic access, AWS IoT SiteWise APIs enable deep integration capabilities. Development teams can embed anomaly detection directly into existing applications and create custom dashboards tailored to their operational needs. The APIs support seamless integration with third-party systems, ensuring insights flow into established workflows. This programmatic access also enables automated configuration and management at scale, ideal for complex enterprise deployments.

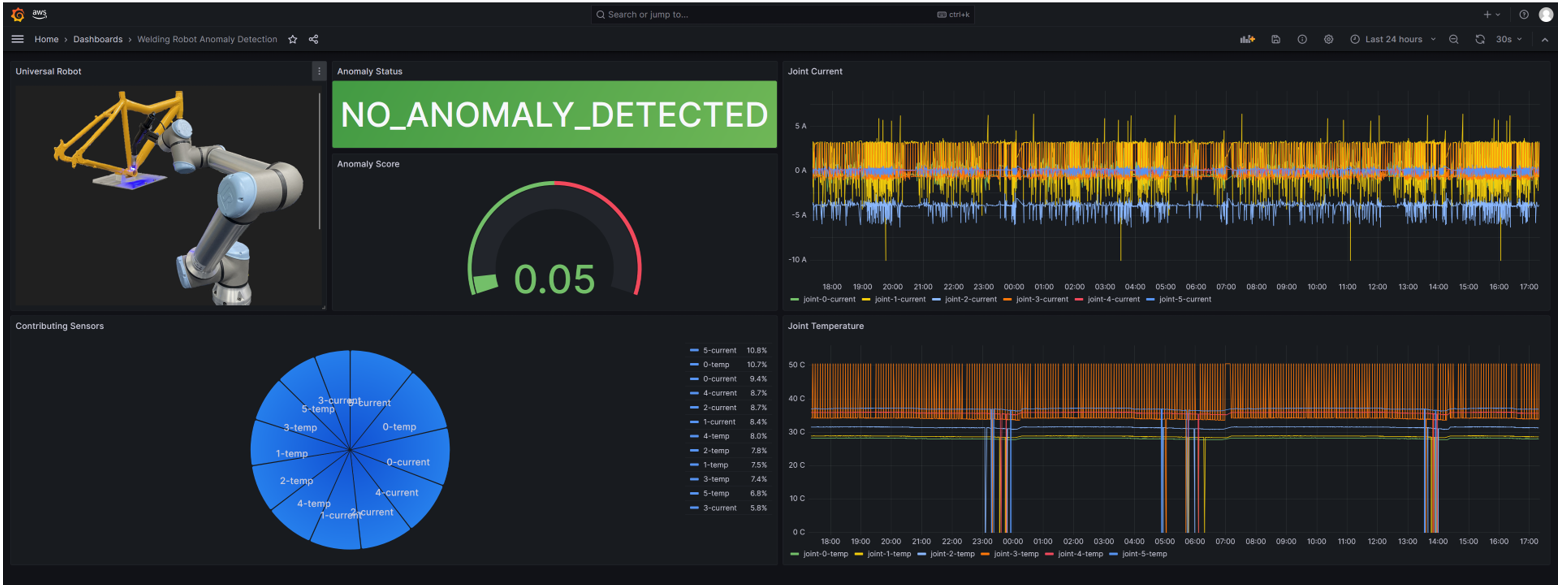

Amazon Managed Grafana Integration

AWS IoT SiteWise Grafana plugin extends anomaly detection results to your existing operational dashboards. You can incorporate anomaly detection results while preserving your current visualization workflows. The plugin supports dynamic exploration of anomaly data, adding predictive capabilities to existing dashboards.

These integration options ensure that native anomaly detection works within your existing operations rather than requiring significant workflow changes. Whether you’re starting with basic monitoring or scaling across a complex enterprise environment, you can implement the solution that best matches your technical capabilities and operational requirements.

Figure 3: Amazon Managed Grafana dashboard showing anomaly interface results and anomaly score

Conclusion

Industrial organizations seek to improve operational reliability while efficiently using resources. Native anomaly detection in AWS IoT SiteWise transforms this challenge into an opportunity by making ML-powered predictive maintenance accessible to maintenance teams of all sizes. By eliminating the complexity typically associated with machine learning implementations, organizations can focus on keeping operations running smoothly and efficiently.

This feature offers rapid time-to-value, where teams can configure anomaly detection in minutes instead of weeks and immediately begin monitoring critical assets. The capability scales from a single asset to an entire fleet, while flexible monitoring options ensure cost-effectiveness.

To learn more, visit the AWS IoT SiteWise Feature page and Getting Started guide. You can also reach out to your AWS account team to discuss how native anomaly detection in AWS IoT SiteWise can benefit your specific use cases.