AWS for Industries

Building a Battery Passport on AWS: Part 1

Article 77(1) of the European Union’s Battery Regulation (Regulation (EU) 2023/1542) (EUBR) mandates that, following February 18, 2027, each light means of transport (LMT) battery, each industrial battery with a capacity greater than 2kWh, and each electric vehicle (EV) battery placed on the market or put into service must have its own electronic record (Battery Passport).

Generally, the EUBR requires that economic operators [1] provide vehicle owners and service and maintenance personnel with certain electronic information relating to the corresponding battery, including material compositions, due diligence of materials, carbon footprint, performance & durability, circularity, etc. To facilitate efficient access to such information, the EUBR mandates that economic operators place a QR code on batteries linking to the Battery Passport containing the foregoing information. The EUBR requires that economic operators meet key requirements such as due diligence reporting obligation (Article 48), economic operator management system (Article 49), risk management obligation (Article 49), Carbon footprint declaration (Article 7), etc. to gather the necessary input data for Battery Passport.

Building a Battery Passport is a complex undertaking because it requires data from various internal and external systems. Battery due diligence policies and carbon footprint declarations are significant milestones of the Battery Passport and that require implementation at least 12 months before the Battery Passport deadline of Feb 2027 for new batteries placed on the market or put into service. In this blog post, you will explore helpful information on how to use AWS services and tools to help build and implement a Battery Passport for an EV.

Given that the Battery Passport is a regulatory requirement, all products, solutions, and tools used by you to comply with the EUBR should be reviewed by your legal counsel.

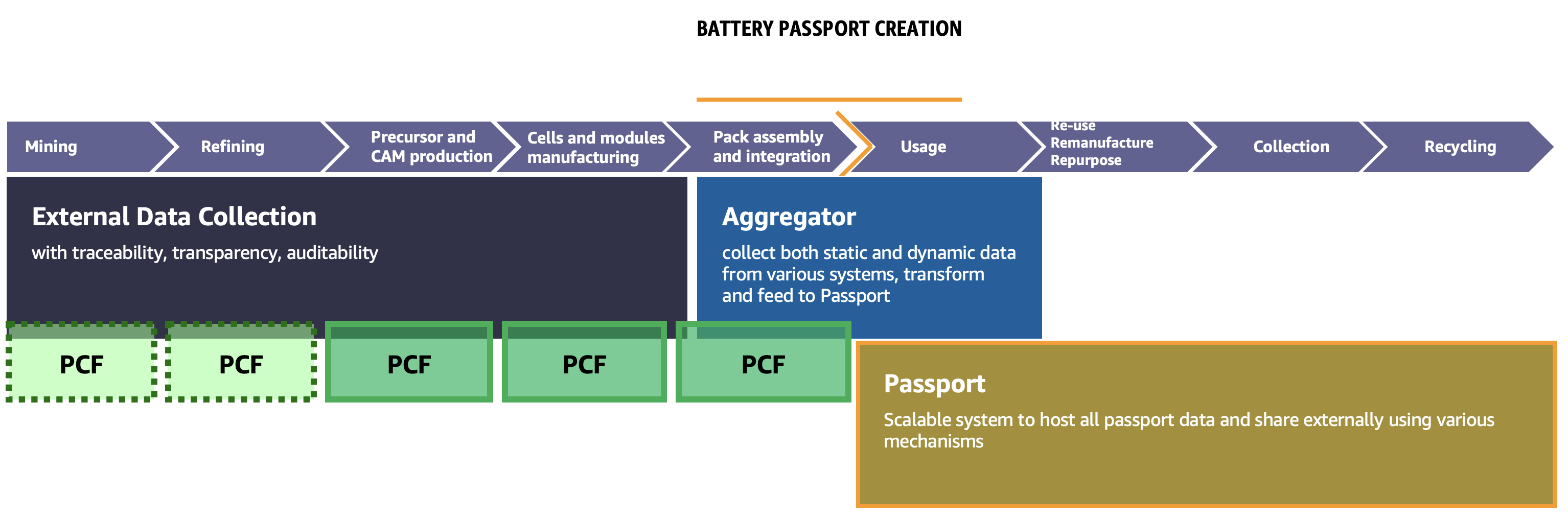

The Battery Pass consortium has published a technical design and guidance for the creation and implementation of Battery Passports. The Battery Pass Content Guidance (Figure 1) outlines the process of collecting data from upstream and downstream stakeholders and processing and storing that data in a passport data repository, discussed below.

Figure 1: Battery Pass Consortium: Content Guidance

Figure 1: Battery Pass Consortium: Content Guidance

Once collected, you need to calculate and transform the data and store it in a passport data repository. Once the processed data is available in the repository, you need to define data governance and access patterns for various stakeholders that align with the access rights described in Article 77(2) of the EUBR. As per DIN—German Institute for Standardization specification DIN-DKE-SPEC 99100, Battery Passport data is categorized in seven data types:

- Identifier and product data

- Symbols, labels, and document of conformity

- Battery carbon footprint

- Supply chain due diligence

- Battery materials and composition

- Circularity and resource efficiency

- Performance and durability

Refer to DIN-DKE-SPEC 99100 for full list of data attributes required as per EUBR.

Solution Building Blocks

Figure 2 below shows the Battery Passport solution’s building blocks. The four high-level building blocks are:

- External Data Collection

- Product Carbon Footprint (PCF)

- Aggregator

- Passport

Figure 2: Battery Passport Solution Building Blocks

1. External Data Collection

This foundation layer gathers static information from across the upstream value chain as highlighted in Figure 2. This layer organizes the data into four critical categories: battery materials and composition, supply chain due diligence, carbon footprint, and circular economy and efficiency.

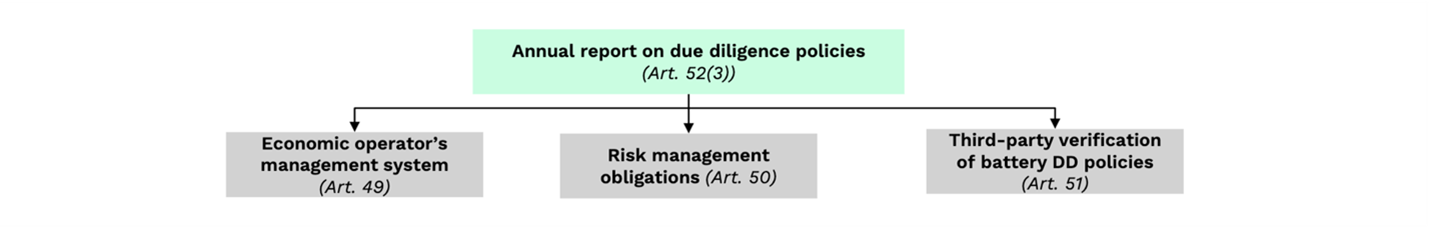

The EUBR requires economic operators (automakers, importers, etc.) to submit annual due diligence reports and implement comprehensive control and transparency systems for their supply chains. This system must provide end users/battery purchasers with chain of custody and traceability mechanisms that identify all upstream supply chain actors. Additionally, operators are required to maintain all relevant records of this system for a minimum period of 10 years. Article 3(42) of the EUBR defines ”battery due diligence” as the obligations of an economic operator in relation to its management system, risk management, third-party verifications and surveillance by notified bodies (an independent organization approved by an EU country to check whether batteries conform to the EUBR) and disclosure of information, for the purpose of identifying, preventing, and addressing actual and potential social and environmental risks linked to the sourcing, processing, and trading of the raw materials and secondary raw materials required for battery manufacturing, including by suppliers in the chain and their subsidiaries or subcontractors.

The EUBR requires that economic operators’ annual due diligence reports (highlight three broad categories of information, as shown in Figure 3:

Figure 4 Due Diligence Policies

Figure 4 Due Diligence Policies

The regulations mandate economic operators to verify these due diligence chains through notified bodies, though they may use third-party verification reports from suppliers. Article 49 of the EUBR requires economic operators to structure their internal management systems in a way to provide end users with access to supporting documentation concerning a battery’s manufacturing, materials, and components, including information related to raw materials, such as their trade name and type, supplier details, country of origin, and chain of custody. The dissemination of this supporting documentation to end users may be completed by providing direct links to annual reports (such as PDFs on company websites) or by incorporating such information within a Battery Passport.

Solution Approach

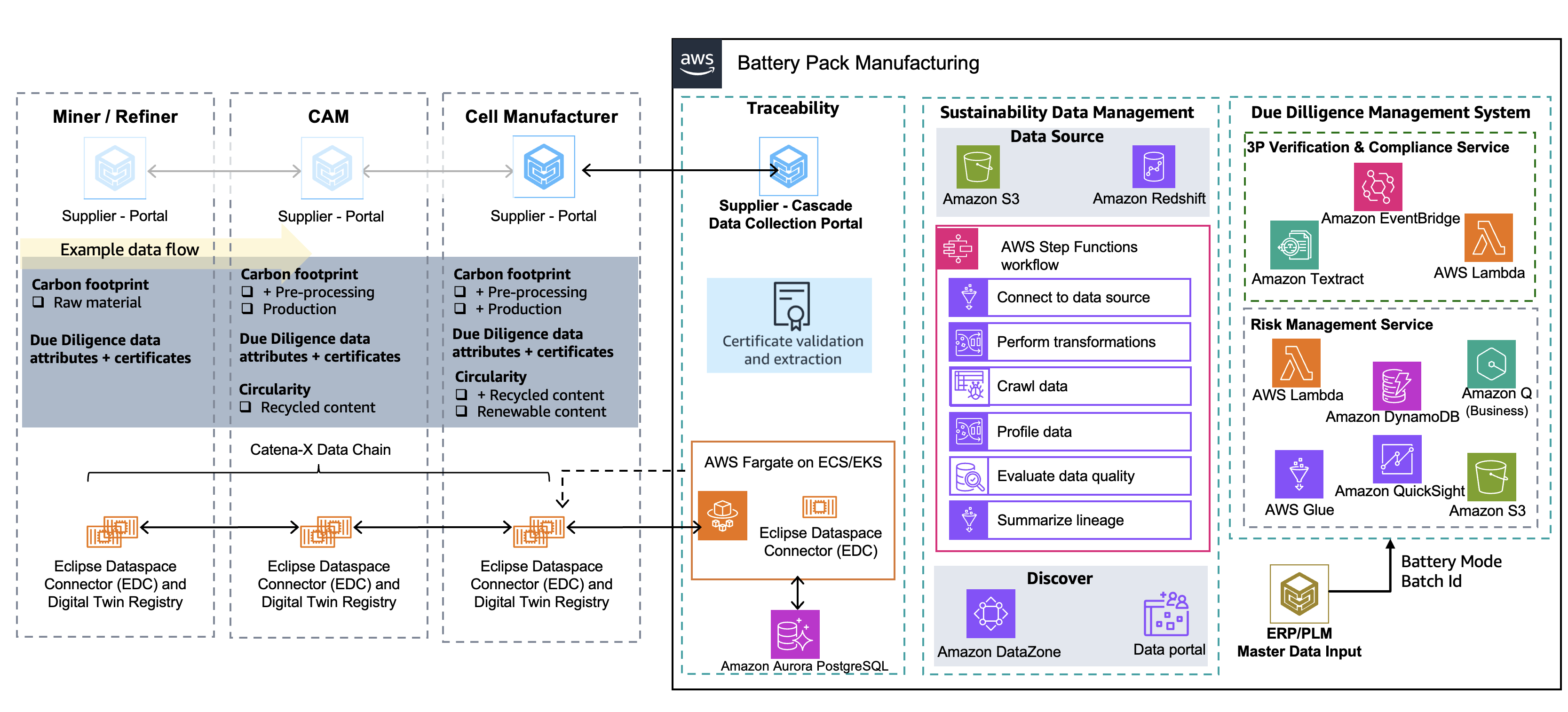

In the automotive industry today, automakers either purchase complete battery packs from suppliers or manufacture their own. When purchasing battery packs, the supplier will provide the automaker with the information and supporting documentation required by the EUBR. This blog assumes that the automaker is the manufacturer of the battery pack. The following architecture diagram (Figure 4) illustrates how the due diligence management system will collect data and help establish a chain of custody.

Figure 4: External Data Collection Solution Approach

Traceability – A Product Lifecycle Management (PLM) and Enterprise Resource Planning (ERP) system will provide crucial inputs to the due diligence management system, including battery model, batch ID, and key upstream supplier information. This information will then trigger the traceability system, initiating data collection from suppliers. It also checks to make sure the collected data is valid and complete by applying basic validation for the certificate.

You need to collect model-specific battery data from each manufacturing site. Several data collection methods can be employed. Here are two approaches:

1. Campaign-based data collection involves creating a campaign and cascading patterns like split and forward to collect data from Tier 1 to Tier N suppliers. To implement this approach, you can use an existing supplier portal with the necessary capabilities or deploy a new portal that takes battery model, manufacturing plant location, and other key information as inputs to trigger the cascade data collection request. AWS Guidance for Product Traceability provides guidance on implementing the traceability system mentioned in the architecture (Figure 4).

2. Catena-X is an open and collaborative data ecosystem designed specifically for the automotive industry to simplify data exchange across companies, e.g. between suppliers and OEMs. If the upstream supplier already exposes data through Catena-X, the Eclipse Dataspace Components (EDC) connector can discover and fetch the necessary data for due diligence. AWS is a member of Catena-X since January 2023. For more details on the deployment architecture of Catena-X and how to get started with data space experimentation on AWS, refer to blog Rapidly experimenting with Catena-X data space technology on AWS.

Sustainability Data Management – instead of being restricted to one specific purpose, data collected during due diligence processes should be structured and accessible for multiple business applications, including Corporate Sustainability Reporting Directive (CSRD) compliance. To enable efficient reuse across various reporting and compliance requirements, this data should be centrally stored and managed through a sustainability data management system. For more information, refer to the Guidance for Sustainability Data Management on AWS.

Due Diligence Management System – The due diligence management system provides two key services: (a) third-party verification and compliance services to perform advanced validation of certificates, such as verifying certificates against issuing authority records, discrepancies in the certificate, and ensuring accurate mapping of the certificate, data, and manufacturing plant location; and (b) risk management services that collect input from various systems and generate a risk assessment dashboard using Amazon QuickSight. The due diligence management system also connects with third-party services for validation. Various certificates, contract documents, and conformity assessments will be stored in the Amazon S3 repository. Amazon Q Business will be used to help extract relevant information as needed, such as the contract obligations for material composition, and make the solution more dynamic and agile. Since the EUBR contemplates further rulemaking with respect to due diligence management systems (See EUBR, Article 48(8)), finer details on the design and operation of such systems are not included in the blog.

2. PCF

The European Union has published a draft delegated regulation for Product Carbon Footprint (PCF) calculations. At the time of publishing this blog, the regulation was not finalized. EUBR Article 7(d) and the draft regulation defines “carbon footprint” as the amount of carbon dioxide equivalent (CO2e) produced per kilowatt-hour (kWh) of total energy provided by the battery over its expected service life. The calculation of the carbon footprint must be conducted across the entire value chain in four distinct lifecycle stages:

1. Raw Material Manufacturing and Processing -Typically secondary data: emission factors from direct measurements, Bill of Material (BOM), stoichiometric calculations of process emissions

2. Manufacturing – Main product production including manufacturing of active material, cell, module and pack. Mandatory company-specific data, also known as “primary data,” covering site or company-specific activity (e.g., utilities, waste, material inputs, and production data)

3. Distribution – Primary transport data from battery manufacturing site to vehicle assembly

4. End of Life. – Disposal type (e.g., landfill, recycling, energy recovery, etc.), material specific recycling rate, collection rate, recycled content, etc.

The draft PCF regulation requires company-specific data for production, while secondary data can be used for raw material manufacturing and pre-processing. Refer to the draft PCF regulation for the detailed requirement. One of the key elements of the PCF requirement is the need to monitor changes in CO2e emissions. If the emissions increase by more than 10%, the economic operator must perform a new carbon footprint calculation and declaration.

Solution Approach

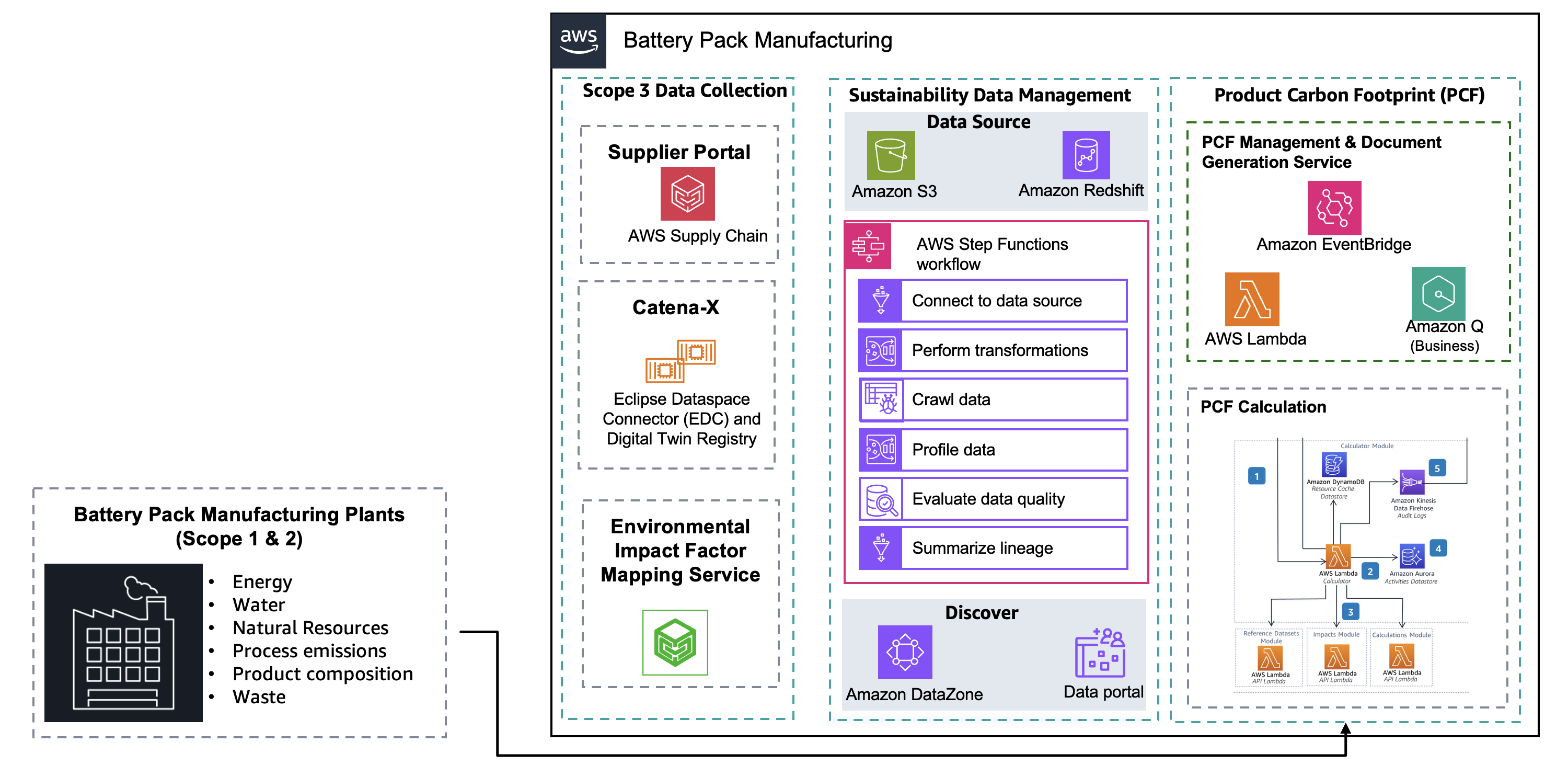

This blog considered a scenario where an automaker purchases cells or modules to construct a battery pack. The PCF solution should be treated as a separate project because it involves multiple integrations with internal and external systems and may require deploying hardware in the manufacturing plant to collect the actual input. Automakers need to collect PCF data reported at four distinct life cycle stages as highlighted earlier.

Figure 5: PCF Solution Approach

Figure 5: PCF Solution Approach

Scope 3 Data Collection – PCF data for upstream suppliers, such as cell manufacturers, Cathode Active Material (CAM) producers, and refiners must be collected using the approach outlined in the External Data Collection section for automakers building battery packs. The primary data needs to be collected from the manufacturing plant. CAM producers, cell manufacturers, and pack manufacturers can use the Guidance for Sustainability Insights Framework on AWS to implement PCF solutions so they can provide the primary footprint data.

Regarding secondary data, on average, 200 to 250 parts and components are needed to build a battery pack. The most effective approach would be to collect the actual Scope 3 data from the suppliers of these parts and components. One option is to utilize the AWS Supply Chain Sustainability capability to create a standardized template for data collection and request the suppliers to provide their Scope 3 footprint data. Alternatively, if a supplier is already sharing Scope 3 data with other customers using the Catena-X EDC data connector, a similar approach can be adopted.

PCF Calculation – Battery pack manufacturers need to deploy a comprehensive PCF solution to calculate the primary footprint data for pack manufacturing. However, since secondary data is permitted in the draft PCF delegated regulation for raw material and processing, economic operators can utilize the Guidance for Environmental Impact Factor Mapping on AWS to calculate its carbon footprint based on the part BOM matching with allowed industry-standard impact factor databases. This Guidance automates the selection of environmental impact factors (EIFs)—sometimes also referred to as emission factors—using foundation models with retrieval augmented generation (RAG). Economic operators can use a sustainability data management system to store and process raw data allowing it to be utilized to help adhere to other regulatory requirements such as CSRD.

PCF Management – PCF declarations should include the methodology used. Amazon Q Business can assist in creating a methodology document based on input from various sources such as data and documents collected from upstream actors. While a real-time data feed for PCF may not be necessary, it’s crucial to collect PCF data at regular intervals to measure the current footprint and report the value. Developing the capability to monitor the footprint is essential because, if it increases by more than 10%, a new PCF declaration needs to be published. The EUBR aims to promote sustainability, so adopting the principle of measure, monitor, and optimize would be key to continuing to reduce the footprint and help organizations achieve their net-zero goals.

The economic operator must update both the PCF declaration, and the Supply Chain Due Diligence report every year and certify the data. A digital solution continuously captures the data with transparency and authenticity. Any changes in downstream suppliers or material requirements trigger a recalculation and report generation.

We have two more building blocks to cover, the Aggregator and the Passport. These will be discussed in “Building a Battery Passport on AWS: Part 2”.

Conclusion

EVs are a means of decarbonizing transportation. Countries outside the European Union also have battery regulations, such as China’s “National New Energy Vehicle Power Battery Traceability Management Platform,” which aims to complete lifecycle tracking and promote a circular economy. India’s “Battery Waste Management Regulation 2022” focuses collecting and recycling waste and batteries, with mandatory recycling targets gradually increasing. The US State of California, through its California Air Resources Board, imposed a battery labeling requirement that aims to enhance chemical transparency, supply chain traceability, and support a circular economy. These regulations have similar objectives and share common data attributes. Since automakers may build EVs in one geography and sell them in different ones, establishing a foundational architecture is essential for scaling EV production and meeting regulatory requirements.

The implementation of a Battery Passport is a complex process, and complete regulations and details are not available from the regulators at the time of publication. If you are an automaker, an economic operator, or an independent software vendor interested in developing a Battery Passport solution, kindly contact your AWS sales team or reach out to us via Ask AWS. We would be pleased to provide guidance to help aid in your development of a Battery Passport and contributions to the circular economy.

[1] The Battery Regulation defines “economic operator” as the manufacturer, the authorized representative, the importer, the distributor or the fulfilment service provider, or any other natural or legal person who is subject to obligations in relation to the manufacture, preparation for re-use, preparation for repurposing, repurposing or remanufacturing of batteries, the making available or the placing of batteries on the market, including online, or the putting of batteries into service in accordance with the Battery Regulation.