AWS HPC Blog

Engineering at the speed of thought: Accelerating complex processes with multi-agent AI and Synera

This post was contributed by Sam Bydlon (AWS), Ram Seetharaman (Synera), Moritz Maier (Synera), and Ryan Qi (AWS)

Imagine this (potentially familiar) scenario: A customer request arrives requiring expertise from multiple departments across your organization. What follows resembles a corporate relay race, but with far less coordination. The request sits in a shared inbox until someone takes ownership, meetings get scheduled and rescheduled, and days pass as the request bounces between specialists with information fragmenting across communications. By the time a response reaches the customer weeks later, the inefficiency is painfully apparent.

This challenge transcends industries. In engineering, it might manifest as a request for quote (RFQ) for an automotive component. In financial services, a complex loan application. In healthcare, a treatment protocol evaluation. Regardless of domain, the fundamental problem remains: complex requests requiring cross-functional expertise move slowly through traditional processes.

Synera, a process automation company, is tackling this challenge head-on in the engineering domain. Their vision is to free engineers from tedious, manual processes and allow them to focus on creativity and innovation. By combining process automation with artificial intelligence and integrating with existing engineering tools, Synera aims to help organizations scale their engineering capacity more efficiently. Where traditional approaches might require weeks of manual effort from multiple engineers, Synera’s approach has the potential to reduce this to minutes or hours, depending on the complexity of the task.

At AWS, we’ve been exploring how multi-agent AI systems—collections of specialized AI agents working together—can revolutionize complex processes across industries. Building on previous work with AI-powered simulation assistants, we collaborated with Synera to implement a prototype multi-agent system that addresses complex engineering tasks like the challenging RFQ process.

While our previous blog demonstrated a single agent using tools to manage and execute simulations, this implementation takes a significant step forward by creating a collaborative network of specialized agents, each with distinct engineering expertise and access to design and analysis tools. This multi-agent approach enables more complex workflows with distributed expertise, specialized reasoning, and coordinated problem-solving across the engineering lifecycle.

For the multi-agent system developed with Synera, Amazon Bedrock served as the large language model (LLM) inference engine powering the AI agents. The performance, reliability and security features of Amazon Bedrock enabled the creation of a robust solution for engineering workflows that involve complex reasoning and analysis.

In this post, we’ll examine how this multi-agent approach works, the architecture behind it, and the efficiency improvements it enables. While the focus is on an engineering use case, the principles apply broadly to any organization facing the challenge of coordinating specialized expertise to deliver faster, more consistent results.

Multi-agent systems: A new paradigm for engineering AI

Artificial intelligence has evolved dramatically in recent years, with multi-agent systems emerging as a particularly promising approach. These systems deploy multiple specialized AI agents that collaborate to solve complex problems—much like teams of human experts working together.

Multi-agent systems distribute expertise across specialized agents, each handling different aspects of a problem while communicating through structured protocols. This approach enables asynchronous task execution, more comprehensive problem-solving through diverse perspectives, and natural scalability as new specialized agents can be added when needed. Additionally, these systems can maintain context across complex workflows and adapt to changing requirements more effectively than single-agent approaches.

Frameworks like LangGraph have documented several architectural patterns for these systems: network architectures where agents communicate directly with each other, supervisor architectures where a central agent orchestrates activities, hierarchical approaches with management layers, and hybrid combinations tailored to specific needs. Each architecture brings different tradeoffs in flexibility, coordination efficiency, and complexity.

Amazon Bedrock provides the foundation model inference capabilities essential for multi-agent AI systems, delivering the performance and reliability needed for complex reasoning tasks. For engineering applications that handle sensitive intellectual property, Bedrock’s enterprise-grade security features offer important protections. Notably, Amazon Bedrock does not store or use input prompts for model training. This combination of high-performance inference and data privacy controls makes Amazon Bedrock particularly well-suited for engineering workflows where both computational demands and intellectual property protection are important.

In practice, these multi-agent systems can serve various organizational goals. While in some cases they may replace certain routine functions, in many valuable implementations their purpose isn’t to substitute human experts but to dramatically enhance their capabilities across domains. By automating routine coordination and analysis tasks, these systems can free knowledge workers to focus on innovation, creative problem-solving, and high-value work that truly demands human ingenuity.

In engineering contexts specifically, multi-agent systems can simulate and analyze entire processes in minutes, generating outputs that specialists can then review—either synchronously or asynchronously—significantly accelerating overall cycle times. Engineers can be elevated to more strategic roles, focusing on verification, refinement, and complex problem-solving rather than routine execution. The result can be both greater job satisfaction and significantly improved productivity, while maintaining appropriate human oversight when needed.

While a single agent or isolated LLM call might handle discrete engineering tasks, the comprehensive nature of engineering processes—from initial requirements to final delivery—demands a team of specialized agents working in concert. A multi-agent approach provides both the specialized knowledge and coordinated action necessary to navigate the full complexity of engineering processes.

Engineering processes are ideal candidates for multi-agent systems due to their cross-functional nature. They require diverse expertise across disciplines, feature sequential dependencies between analysis stages, contain decision points that create branching paths, demand iterative refinement through feedback cycles, and involve complex data handling across multiple tools and formats.

Synera has recognized this potential and developed an approach specifically designed to tackle complex engineering processes through multi-agent systems, which we’ll explore next.

Synera’s vision for engineering process automation

Synera is developing a new approach to engineering process automation by placing AI agents at the center of their solution. Their vision goes beyond digitizing existing workflows—they’re reimagining how engineering teams operate in an AI-enhanced world.

Synera’s process automation approach consists of four interconnected elements:

- Modeling of engineering workflows through accessible visual programming environments, allowing organizations to capture specific workflows without extensive programming knowledge.

- Creating connections between Computer-Aided X (CAx) tools—including design, engineering, manufacturing, and simulation software—that traditionally operate in isolation.

- Publishing these automated workflows as callable tools with standardized interfaces.

- Making these tools accessible to AI agents through API interfaces.

Synera’s platform provides an intuitive way for engineers to capture and automate their expertise. Figure 1 shows Synera’s visual programming environment where engineers can design complex workflows by connecting various process nodes through a graphical canvas. The interface displays modules representing different engineering tools including CAD software, FEA solvers, and analysis components that can be connected using visual links to represent data flow.

Engineers can configure parameters for each process step without writing code, enabling them to create sophisticated automation workflows that are later accessible to AI agents through standardized APIs. This visual approach effectively translates engineering expertise into programmatic tools that can be leveraged throughout an organization.

Figure 1 – Synera’s visual programming environment for engineering process automation.

The result is a seamless flow of information across the entire engineering lifecycle, connecting previously siloed tools, teams, and expertise for unprecedented levels of automation and collaboration. This workflow automation platform creates the foundation for implementing multi-agent engineering systems.

What makes Synera’s approach powerful is how it captures and amplifies engineering expertise. The platform encapsulates the knowledge of experienced engineers in executable workflows, making specialized expertise consistently available throughout the organization. This accelerates access to critical engineering insights without requiring direct involvement from specialists for every task. Engineers remain essential for creating these workflows, validating outputs, and handling novel challenges, while routine analyses can proceed at dramatically accelerated speeds. This approach democratizes access to engineering knowledge while optimizing how engineering talent is deployed.

This transformation from theory to practice was demonstrated in a prototype collaboration with Synera that explored an RFQ response process that traditionally required 2-3 weeks and six engineers to complete. Using the multi-agent approach, once the system was built, the entire RFQ analysis could be simulated in minutes—demonstrating the potential for dramatic improvement in efficiency. This acceleration didn’t compromise quality; the consistency and thoroughness of analysis was maintained or even improved.

By combining workflow automation with multi-agent AI systems, Synera aims to create a foundation for “Engineering at the Speed of Thought”—where teams can translate ideas into reality with unprecedented speed while maintaining the human creativity that drives innovation.

Implementation: A multi-agent architecture for engineering RFQ processing

The collaboration with Synera resulted in a multi-agent system designed to handle complex engineering RFQs. Before diving into technical details, let’s clarify what is meant by a multi-agent system in this context.

A multi-agent system consists of multiple AI agents working together to accomplish tasks that would be difficult for a single agent. Each agent in the RFQ system combines:

- A foundation model (powered by Amazon Bedrock) that provides reasoning and language understanding capabilities

- Access to specific Synera workflow tools that connect to engineering software

- A clearly defined role with specific responsibilities in the overall process

These agents communicate with each other through structured messages, forming a network where information flows along predefined paths but can adapt based on specific requirements of each task.

For the RFQ prototype system, we chose LangGraph as the orchestration framework to coordinate the agents’ interactions and manage their conversation flows. This represents just one possible implementation approach for multi-agent orchestration.

To power the individual agents’ reasoning capabilities, Amazon Bedrock provided secure and scalable foundation model inference essential for enterprise engineering environments.

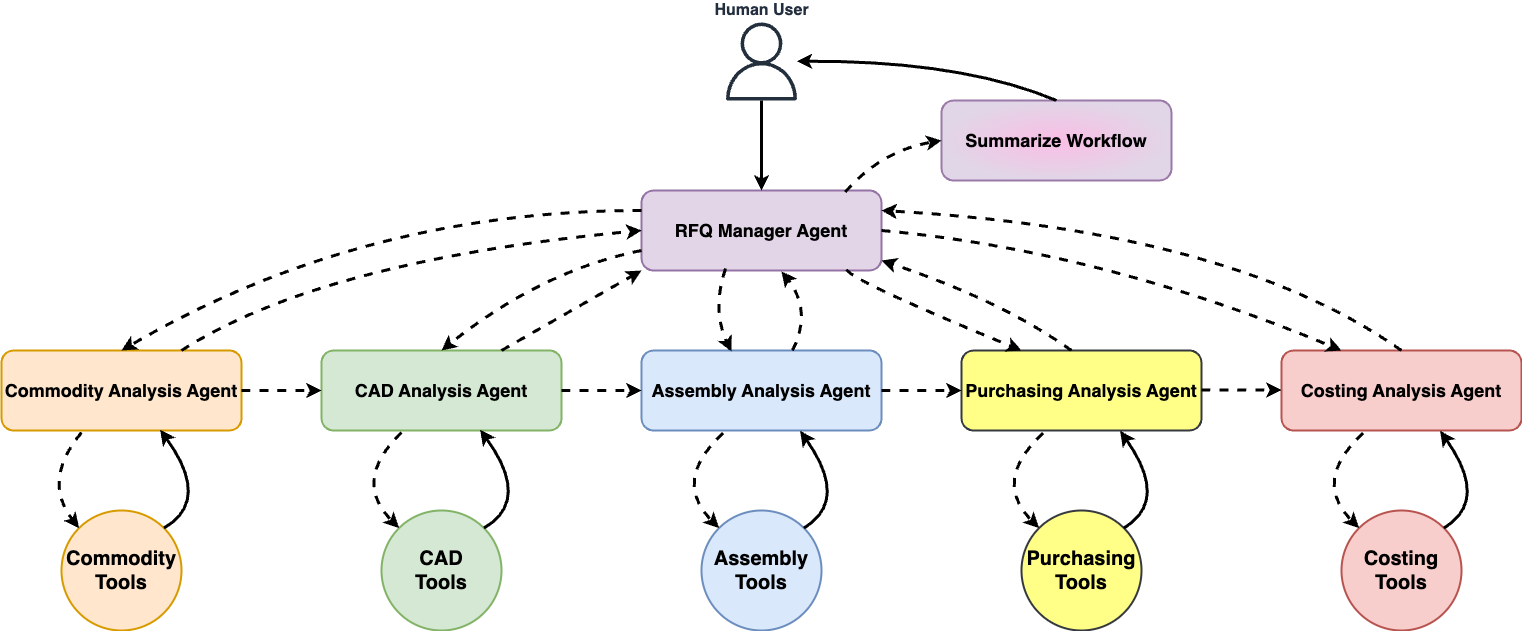

Figure 2 – Multi-agent architecture for engineering RFQ processing.

Figure 2 illustrates the multi-agent architecture developed for engineering RFQ processing. At the heart of the RFQ system is the RFQ Manager Agent, which serves as the central coordinator. This central agent communicates with five specialized engineering agents arranged around it: Commodity Analysis Agent, CAD Analysis Agent, Assembly Analysis Agent, Purchasing Analysis Agent, and Costing Analysis Agent.

The RFQ system architecture combines elements of both supervisor and network approaches—roughly 75% supervisor elements and 25% network elements, though such categorizations are approximate in hybrid architectures. The network elements allow specialized agents to communicate directly when appropriate, thus benefitting from both guided coordination and direct collaboration. The diagram shows information flows between these agents, with the RFQ Manager coordinating the overall process by routing queries to appropriate specialist agents based on the requirements.

The implementation features five specialized agents representing different engineering disciplines:

- The Commodity Analysis Agent evaluates RFQ specifications and determines optimal system configurations

- The CAD Analysis Agent performs geometric validation and generates volumetric calculations

- The Assembly Analysis Agent determines optimal joining methods and manufacturing approaches

- The Purchasing Analysis Agent evaluates supply chain considerations including availability and lead times

- The Costing Analysis Agent performs final calculations for unit and total costs

Each specialized agent has access to specific Synera workflow tools through standardized APIs, allowing them to perform their domain-specific analyses.

The RFQ Manager Agent serves as both the entry point for user requests and the final summarizer of results. This central agent receives initial requests from human users, maintains awareness of the full RFQ context, determines required analyses, and orchestrates the overall workflow, ultimately returning the final results.

The independent, specialized agents each contribute their domain expertise while maintaining the ability to return control to the RFQ Manager when they’ve completed their analysis or when they recognize that another agent would be better suited for the next step. This dynamic routing between supervisor and specialists creates a flexible system that adapts to the specific requirements of each query.

The system uses a custom “guided waterfall” communication pattern—a hybrid approach where each specialized agent can either proceed to the next agent in sequence or return to the supervisor for redirection. This pattern, which emerged from experimentation with multi-agent architectures, creates an efficient workflow where analyses follow a predetermined path when appropriate, while allowing the central RFQ Manager to dynamically route information, bypassing unnecessary steps or redirecting based on specific requirements. This balance between structured flow and adaptive routing proved particularly effective for engineering workflows with complex dependencies

A key strength of this implementation is how agents interact with Synera’s process automation platform. Synera encapsulates engineering workflows as parameterized Synera files (.syn) ranging from simple analyses to complex simulations. These workflows are exposed as APIs through a Synera Run server, allowing agents to invoke precisely the engineering capabilities needed at each stage.

A Synera Run server is a deployment that organizations can set up as a central hub for hosting and executing engineering workflows. Engineers publish their automation workflows to these servers with standardized interfaces, effectively turning complex engineering processes into callable APIs. These published workflows can then be invoked by users or AI agents through a consistent interface.

This workflow-as-API approach enables the agents to access everything from basic geometric calculations to complex computational simulations using the same interface. The engineering logic remains encapsulated in Synera’s workflows, while agents handle execution, interpretation, and decision-making.

This multi-agent architecture successfully addressed the specific challenges of RFQ processing by balancing centralized oversight with specialized autonomy, allowing each component of the system to contribute its unique strengths to the overall solution.

Demo: The system in action

To demonstrate the capabilities of the RFQ multi-agent system, several scenarios were created involving engineering RFQs with varying requirements. For demonstration purposes, a synthetic dataset was used to showcase the system’s functionality, while ensuring the workflow logic remained representative of real-world engineering processes.

Figure 3 presents a video demonstration of the multi-agent system in action, showing how it processes engineering RFQs with varying complexity. The demonstration illustrates the collaborative intelligence of the system as it analyzes, reasons through, and responds to complex engineering queries. The video shows the RFQ Manager Agent orchestrating collaboration between specialized engineering agents, each contributing their domain expertise to build a comprehensive analysis. The demonstration highlights how the system handles both initial queries and follow-up requests with remarkable efficiency, transforming processes that traditionally take weeks into operations that complete in minutes.

Figure 3 – Video demonstration of the multi-agent system processing engineering RFQs.

Throughout the video, the specialized agents access their respective workflow tools through a Synera Run server. When an agent in the demonstration needs to perform an analysis, it connects to the appropriate workflow on the Run server, which executes the engineering logic while maintaining isolation between sessions. While this demonstration showcases RFQ-specific analyses, the same approach enables integration with various engineering tools an organization already uses, including CAD software, simulation packages, and analysis tools, allowing AI agents to leverage specialized engineering expertise encoded in executable workflows.

In the demonstration, the user submits an RFQ with specific requirements: “We need a system with a flow rate of 300 m³/h, pressure drop of 1.33 bar and parent mass of 250 g. It has production volume of 7000 parts in standard delivery option.”

This triggers the full multi-agent workflow:

- The Commodity Analysis Agent determines optimal specifications based on the requirements

- The CAD Analysis Agent validates the geometry and calculates component volumes

- The Assembly Analysis Agent recommends an appropriate joining method

- The Purchasing Analysis Agent assesses supplier options and lead times

- The Costing Analysis Agent calculates the final pricing

The system provides a comprehensive response including technical specifications, manufacturing approach, lead time estimates, and project cost projections.

The user then tests the system’s flexibility with a follow-up query: “Compare quotes for this system for two other production volumes – one for 30 and one for 10000.” This request doesn’t require the full agent sequence, as the technical specifications remain unchanged. Instead, the system engages only the relevant agents (primarily Costing) to generate comparative quotes with detailed breakdowns for each production volume.

The entire process demonstrates how the multi-agent system intelligently routes queries to the appropriate agents, invokes only the necessary workflows, and delivers comprehensive responses in minutes rather than weeks.

Results and business impact potential

The prototype RFQ multi-agent system demonstrates significant potential for transforming engineering processes. In this demonstration, we’ve seen RFQ analyses that would traditionally take days or weeks simulated in just minutes. This dramatic reduction in processing time opens exciting possibilities for engineering organizations.

The business benefits extend well beyond speed. By automating routine analyses and coordination tasks, systems like this allow engineers to focus more on innovation and customer engagement rather than repetitive calculations. Organizations can potentially:

- Respond to customer inquiries significantly faster, improving win rates for competitive bids

- Maintain consistent analysis quality regardless of which team members are available

- Handle multiple RFQs simultaneously, even during peak demand periods

- Deploy engineering talent on high-value design and innovation activities

- Reduce errors through standardized analysis workflows

- Democratize access to specialized engineering expertise across the organization

This technology represents a significant shift in how engineering could be done. As with previous waves of technological advancement, roles will evolve. Forward-thinking engineers will find opportunities to become workflow architects and AI system designers, applying their domain knowledge in more leveraged ways. Organizations that embrace this transition thoughtfully can eliminate bottlenecks, improve responsiveness, and reduce dependency on key personnel availability—all while creating new high-value roles that blend engineering expertise with automation capabilities.

For organizations implementing similar systems, the potential benefits scale with the complexity of their engineering processes and the volume of requests they handle. An engineer who previously spent most of their time on routine analyses can transition to overseeing and refining automated processes, handling exceptions, and focusing on complex engineering challenges that truly require human creativity and judgment.

Conclusion

This collaboration with Synera demonstrates the transformative potential of multi-agent AI systems for engineering process automation. By combining specialized AI agents powered by Amazon Bedrock with parametric access to engineering workflows through Synera’s platform, this implementation has shown how processes that traditionally require weeks can be simulated in minutes.

The power of this approach extends beyond simple time savings in two key dimensions. First, it democratizes engineering expertise throughout organizations by allowing non-technical stakeholders to get answers to complex technical questions without requiring an engineer’s direct involvement. Second, it enables engineers to evolve their roles toward innovation and creative problem-solving rather than repetitive calculations and analyses.

For engineering organizations facing pressure to respond quickly to customer requests while maintaining high standards, multi-agent systems offer a promising path forward—accelerating routine processes, reducing dependency on specific personnel, and creating more responsive operations.

As AI capabilities evolve and engineering tools become increasingly accessible through APIs, multi-agent systems will play an increasingly important role in engineering organizations—empowering them to work at the speed of thought.

If your organization is interested in exploring how multi-agent systems could transform your business processes, we encourage you to reach out to your AWS account team or solutions architect to discuss implementation strategies. For specialized guidance on these advanced approaches, your account team can contact the AWS Advanced Computing, Emerging Technologies team.

To learn more about Synera’s engineering process automation platform featured in this post, visit synera.io.