AWS Partner Network (APN) Blog

Unlocking the Power of AI in Manufacturing with PTC Kepware+ on AWS

By Raymond Labbe, Senior Principal Solutions Consultant, Fellow Engineer – PTC

By Stephen Sponseller, Senior Director, Kepware Strategic Partnerships – PTC

By Manish Yashvant, Principal Partner Development Manager, Industrial Solutions – AWS

By Preet Virk, Principal Partner Solutions Architect, Industrial Solutions – AWS

|

|

Fragmented systems, legacy equipment, and incompatible protocols create data silos, slow innovation, and pose cybersecurity risks. Manufacturers are racing to modernize operations and harness data-driven artificial intelligence (AI) insights to reduce downtime and improve efficiency and quality. The collaboration between PTC Kepware and Amazon Web Services (AWS) addresses these challenges.

This blog post details how integrating Kepware+ with AWS improves efficiency, lowers costs, and enhances operational intelligence in a secure, scalable internet of things (IoT) architecture for Industry 4.0 and sustainability.

Why Industrial Connectivity Matters

Industrial environments include diverse sensors, machines, and control systems using different languages and protocols. This complexity limits data collection, delays decision-making, and reduces visibility. Kepware+ integrated with AWS IoT services, resolves these issues by:

- Standardizing Data Access: Connecting industrial devices (PLCs, SCADA systems, sensors, HVAC, and manufacturing equipment) to the cloud, regardless of protocol or manufacturer.

- Enabling AI and Real-Time Insights: Streaming data to AWS IoT Core or at the edge using AWS IoT Greengrass for immediate analysis and action.

- Supporting Predictive Actions: Use AWS IoT SiteWise and Amazon SageMaker to detect anomalies, predict failures, and optimize processes.

Organizations reduce unplanned downtime, optimize asset performance, and gain real-time visibility into critical operations, essential for industries where downtime is costly.

Real-World Impact with Kepware and AWS

Predictive Maintenance

A global automotive manufacturer, grappling with frequent production halts due to unexpected equipment failures, deployed Kepware+ connectivity platform and reduced downtime by 40% and saved $2.8 million annually by:

- Aggregating machine data across 15 global plants into an Amazon Simple Storage Service (Amazon S3) data lake.

- Using AWS IoT SiteWise and Amazon SageMaker to analyze historical and real-time data for failure prediction.

Wind Farming Business Intelligence and Analytics

A large renewable energy provider needs visualization and analytics of their wind farm operations to identify underperforming assets and make informed next-step decisions by:

- Deploying Kepware+ and AWS IoT Greengrass to access machine data from 2,200 wind turbines and send the encrypted data securely to the AWS IoT Core.

- Storing data in an Amazon S3 Data Lake and using Amazon Redshift for analysis.

- Automating corrective actions and issuing work orders when necessary. The engineering team has the authority to take remediation actions based on observations from the analytic charts. It takes remote corrective action from the central control room and attempts to return the asset to the optimal state. In case this fails, they issue a work order for a physical inspection of the asset at the site.

- Customer achieves up to 15 percent performance improvement at up to 50 percent lower costs relative to equivalent previous generation instances.

Energy Optimization

An oil and gas enterprise reduced energy consumption by 15% across its drilling operations by:

- Connecting sensors and control systems via Kepware+ to AWS IoT Core for real-time energy monitoring.

- Using AWS IoT SiteWise and Amazon QuickSight to identify inefficiencies and guide operational adjustments.

Supply Chain Visibility

A food and beverage manufacturer improved supply chain visibility by 30%, cutting waste and ensuring on-time deliveries by:

- Connected Production Lines: Kepware+ integrated data from production equipment into AWS IoT Greengrass for localized edge processing.

- Enhanced Traceability: AWS IoT SiteWise and Amazon Redshift offered real-time tracking of raw materials and finished goods.

Building Management Optimization

Large campuses or commercial buildings can centralize facility data for HVAC, lighting, and energy systems to reduce energy costs and emissions by:

- Protocol Translation: Kepware+ converted legacy BACnet, Modbus, and other protocols into standardized data for consumption by operational technology (OT) and information technology (IT) systems.

- Real-Time Monitoring: Data streams into AWS IoT Core, with Amazon QuickSight dashboards providing a comprehensive view of energy usage and occupancy trends.

Pharmaceutical Track & Trace

Compliance with regulations like FDA 21 CFR Part 11 and ensuring product quality are paramount in pharma by:

- Secure Data Logging: Kepware+ aggregates data from production lines and sends to Amazon S3 with versioning and encryption for storage.

- Quality Control: AWS IoT SiteWise and Amazon Athena detect early deviations in product quality, enabling rapid corrective action.

- Regulatory Compliance: Centralized, time-stamped data logs simplify audits, reduce manual reporting, and enhance traceability.

How Kepware and AWS Work Together

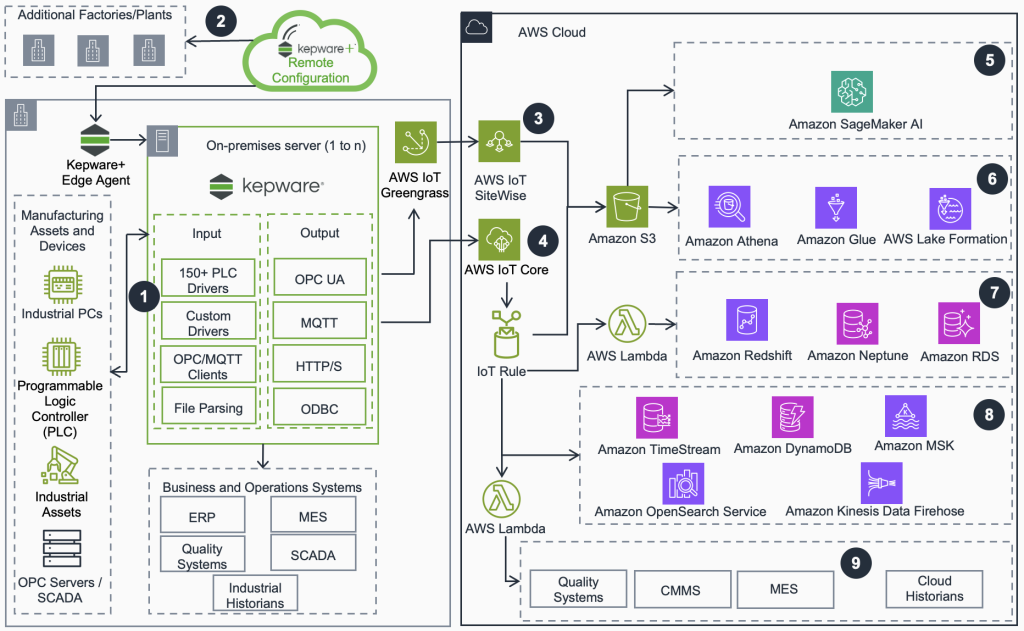

Figure 1 below is a high-level view of how Kepware+ and AWS allow seamless industrial connectivity, secure data ingestion, and advanced analytics.

Figure 1: Guidance for Kepware+ with AWS services

PTC Kepware+ standardizes secure data exchange between industrial devices and AWS, enabling real-time data streaming by:

- Kepware+ delivers comprehensive industrial connectivity by seamlessly connecting to virtually any industrial device, including PLCs, sensors, and SCADA systems through its extensive library of pre-built drivers. IoT Gateway with MQTT support, enable secure communication between shop floor systems and enterprise applications.

- Enterprise Management is available in Kepware+ to securely manage industrial connectivity for all locations throughout the enterprise via single pane of glass. This enables remote configuration from any location while supporting Active Directory integration for enhanced security and user management.

- Kepware+ streams near real-time data directly to AWS IoT SiteWise using OPC UA collector component of AWS IoT Greengrass. Calculate and visualize metrics from telemetry data using AWS IoT SiteWise Monitor.

- Kepware+ MQTT Client agents facilitates communication with AWS IoT Core to post asset data and Industrial IoT data as well.

- Use AWS AI/ML services such as Amazon SageMaker to build, train, and deploy ML models.

- Use AWS Glue to discover, prepare, and integrate data from Amazon S3 at scale. Create, run, and monitor extract, transform, load (ETL) pipelines through a centralized data catalog to load data into your data lakes. Query Amazon S3 data using SQL with Amazon Athena. AWS Lake Formation discovers, catalogs, cleanses, and transforms your data sources.

- To record the measurement from MQTT message, AWS IoT Core topic triggers AWS Lambda functions to ingest data into Amazon Redshift, Amazon Neptune or any Amazon RDS Database. Use Amazon Redshift to store structured data sets and analytics results in a data warehouse.

- Publish Telemetry data in near real-time to AWS IoT Core triggers IoT Core rules. This reliably streams the data into an Amazon S3, Amazon DynamoDB, Amazon OpenSearch Service, Amazon Kinesis Data Firehose, Amazon Timestream, or Amazon Managed Streaming for Apache Kafka (Amazon MSK).

- OT data tapped by Kepware+ can go into business systems running on AWS Cloud like Quality Management, CMMS, MES, or Cloud Historians via AWS IoT Core. Configured IoT Rule can trigger an AWS Lambda function that encapsulates the logic to post data to these system via API calls.

It integrates with AWS analytics, AI/ML, and data management services to store, process, and analyze industrial data at scale, driving enterprise-wide insights and enable building automated workflows.

Turning Siloed Data into Insights

PTC Kepware unites deep industrial expertise with AWS’s cloud innovation to deliver solutions that:

- Simplify Complexity: Build a foundation for OT data access that is interoperable across the enterprise, with pre-built drivers and integrations to accelerate time to value and enterprise scale.

- Ensure Security: End-to-end encryption and edge security features (AWS IoT Greengrass) protect data from the device level to the cloud.

- Scale Effortlessly: From single-site pilots to global rollouts, the solution grows with business needs, powered by AWS’s global infrastructure.

Through this collaboration, customers can overcome data silos, share insights more easily, and optimize anything from a single production line to a global enterprise.

Conclusion

The future of manufacturing and industrial operations hinges on connectivity, intelligence, and agility. By embracing Kepware+ best practices with AWS, businesses unlock the full value of their industrial data, converting operational hurdles into growth opportunities. Whether your goals involve predictive maintenance, energy optimization, compliance, or supply chain resilience, the Kepware and AWS collaboration provides a proven, secure, and scalable path to industrial innovation.

Get started with Kepware+ Industrial Connectivity Solutions and download the brochure.

.

PTC – AWS Partner Spotlight

PTC is an AWS Partner and is an IoT competency partner. This designation recognizes PTC’s ThingWorx® IoT platform, which enables organizations to create IoT applications and generate business value for a variety of use cases, including (though not limited to) intelligent factories, smart cities, energy, automotive, transportation, and healthcare. Achieving the AWS IoT Competency differentiates PTC.